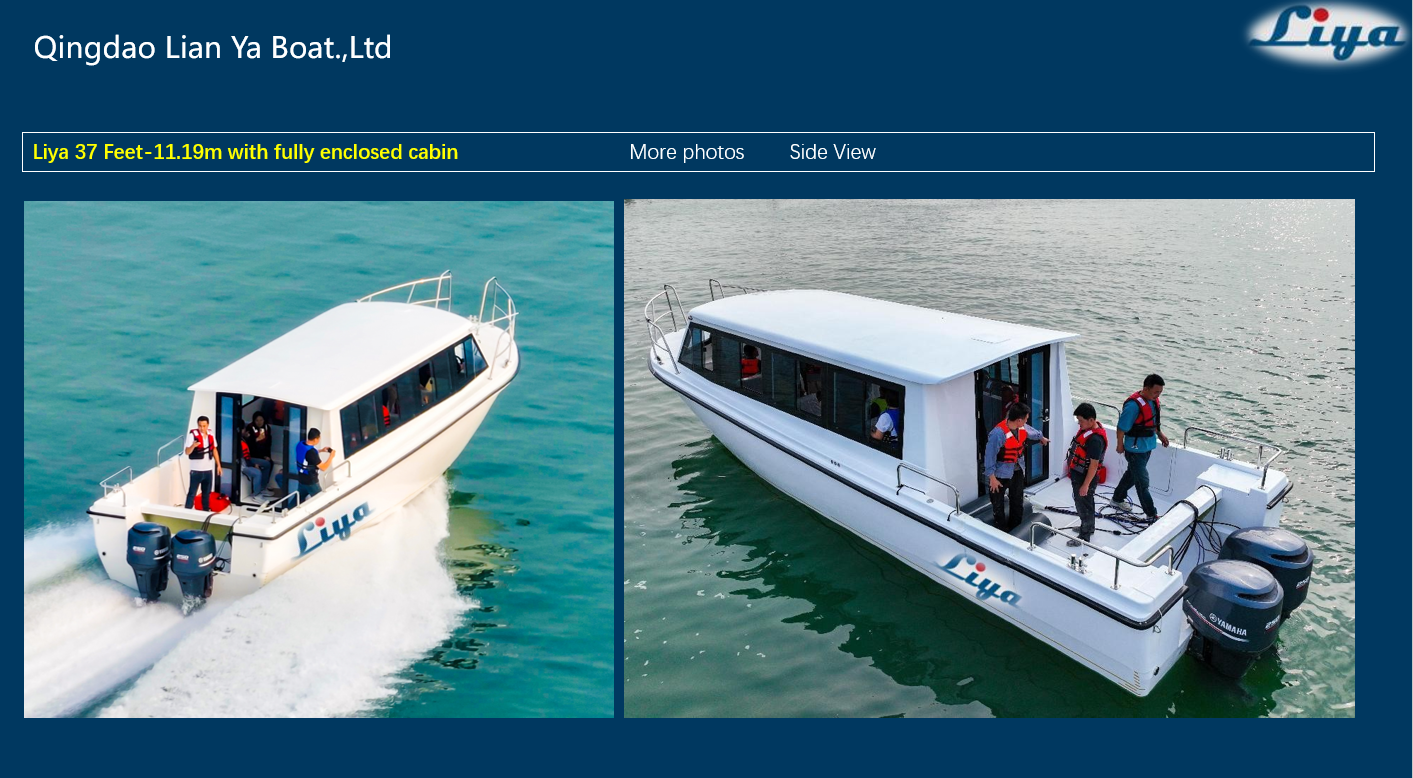

37 Foot Fiberglass hull office Boat with cabin for 20 persons.

Fiber office boat with 500HP engine

Single or twin engines for choice

Liya 37 Foot Cabin Fiberglass Boat For 20 People used for commerical, transportaion, or family etc

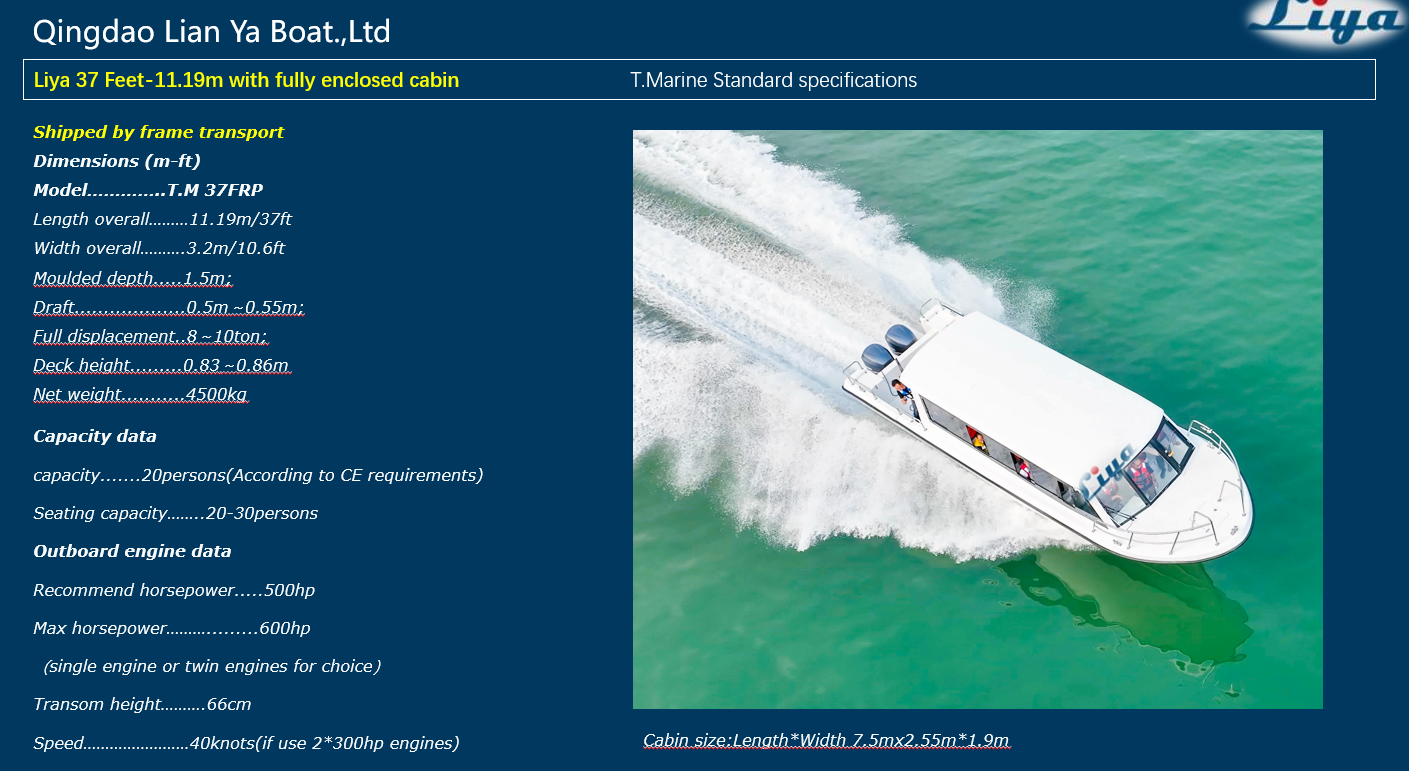

Outboard engine/Inboard engine:

Recommend Horsepower---500HP

Max Horsepower-----------600HP

Single engine or twin engines both available

More videos please check :https://www.youtube.com/@LiyaBoat

Liya 37 Foot Cabin Fiberglass Official Boat for 20 passenger Specification

1. 11.19m passenger boat characteristics

Liya 37 Foot Cabin FRP Official Boat Safety Operation & Maintenance Guide

Key points for safe operation

Pre-sail inspection

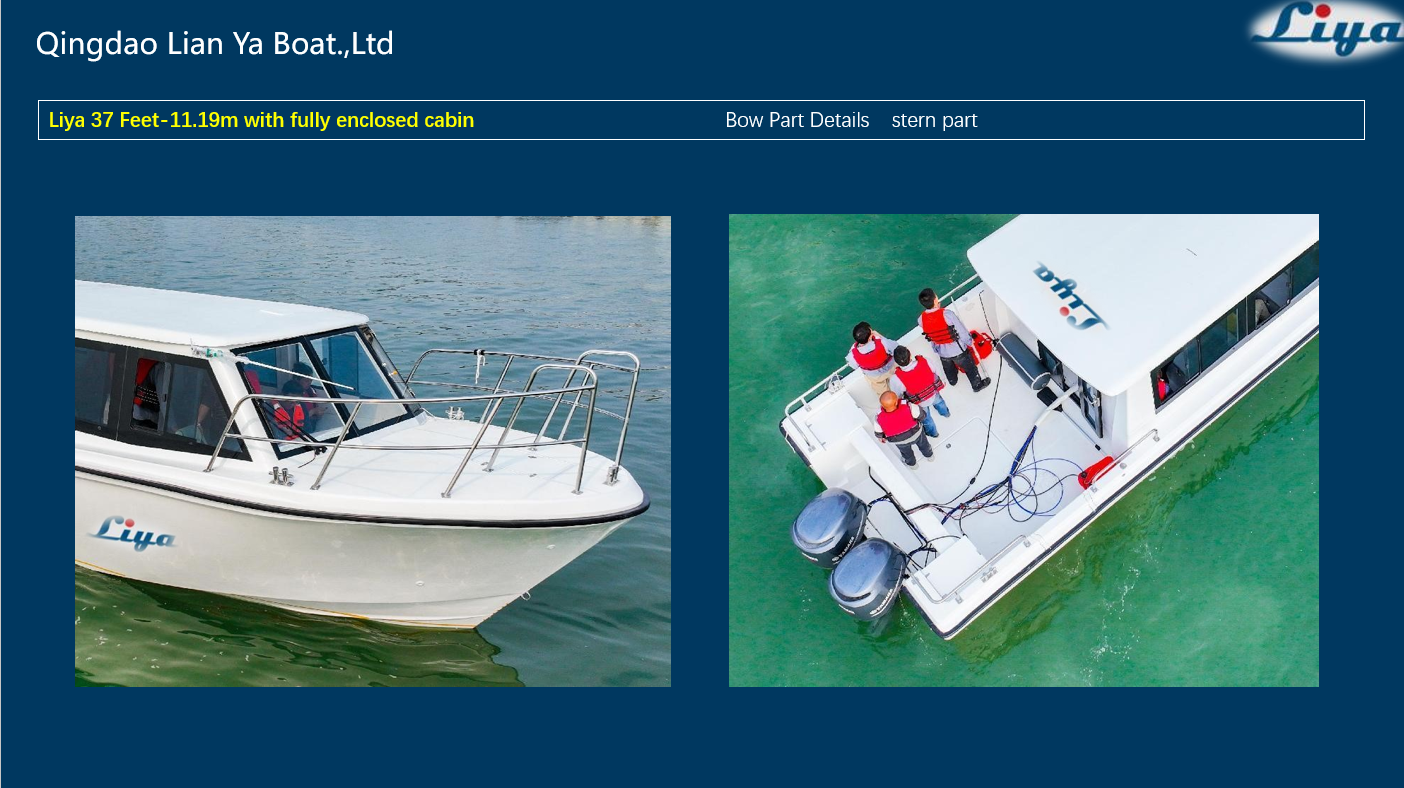

Hull inspection: Confirm that there are no cracks, delamination or impact marks on the surface of the FRP, and focus on the area below the waterline and the joints.

Equipment test: Check whether the navigation equipment, drainage system, fire-fighting and life-saving facilities (life jackets, life rafts) are normal.

Precautions during navigation

Avoid hard collisions: You need to be careful to avoid hard objects such as reefs and floating ice to prevent the hull from breaking.

Load balance: Strictly follow the passenger capacity limit to ensure that passengers are evenly distributed to avoid hull tilting or center of gravity shifting.

Response to bad weather: Slow down when encountering strong winds and waves, keep the bow facing the waves, and reduce the impact stress on the hull.

Emergency handling

Hull water seepage: Immediately start the drainage pump, check the damaged location and temporarily seal it (such as using epoxy resin glue).

Structural damage: If large-scale cracks or delamination are found, dock nearby and contact professional repairs.

Daily maintenance measures

Cleaning and protection

Fresh water flushing: flush the hull and deck after each use to remove salt, oil and prevent corrosion.

Ultraviolet protection: apply FRP special protective wax (containing UV absorber) regularly to slow down the aging of resin.

Scratch repair: shallow scratches are treated with polishing agent; deep cracks need to be polished, filled with resin and re-coated with gel coat.

Structural maintenance

Water seepage detection: knock on the hull every year to check whether there is delamination and empty sound, and it needs to be peeled and repaired if found.

Joint reinforcement: check the connection between FRP and metal parts (such as guardrails and engine base) and strengthen the sealant in time.